Grouting Sleeve

Mar 15, 2019

Grouting Sleeve

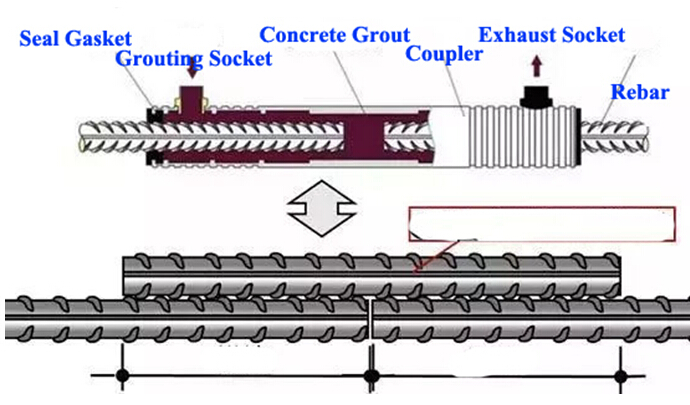

This method is called full-sleeve grouting and is used for beam reinforcement in prefabricated buildings.

Similarly, there are other methods for prefabricated wallboard reinforcement connections:

Semi-grout sleeve connection

Threaded sleeves can save a lot of steel in construction.

However, in prefabricated buildings, there is no way to screw the prefabricated wallboard.

So a technique has been created - a semi-grout sleeve connection,

That is, the straight threaded sleeve is connected to the grouting sleeve.

Semi-grouting construction process

Then the construction process of the semi-grouting sleeve is simple and simple.

When the factory is prefabricated, the sleeve is attached to the steel bar to be pre-formed,

Pull it to the site for assembly.

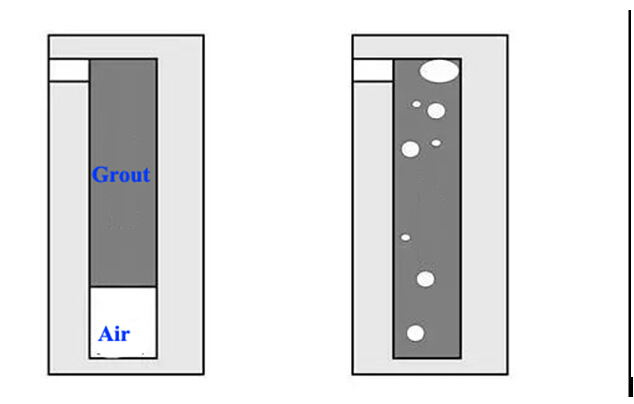

There is an important job before the grouting of the steel bars after the grouting – soot blowing.That is, use a high-pressure air pump to blow out all the things inside,The things inside, including the air,

If the air cannot be discharged when grouting,There are two consequences.

So we usually reserve two holes in the sleeve grouting. Slurry holes and grout holes.

Blocking the hole after the grout is finished is considered complete. In addition, there is an inverted insertion grouting process worth learning. Reverse insertion grouting process.

In fact, "inverted interpolation" has exposed a lot of things, in general, the sleeve is left at the bottom of the wall.When the upper wall panel is hoisted, Use a mirror to insert a steel bar into the sleeve. Inverted interpolation. Just leave the sleeve on the top of the wall. Grouting the upper wall panel before installation. Then install the steel plate in the opposite direction.

Previous: 40 sets of equipments shipped to South Africa Liugong into the South African coal marketstrongly

Next: The Chinese railway construction was invested by RMB 850 billion in 2019